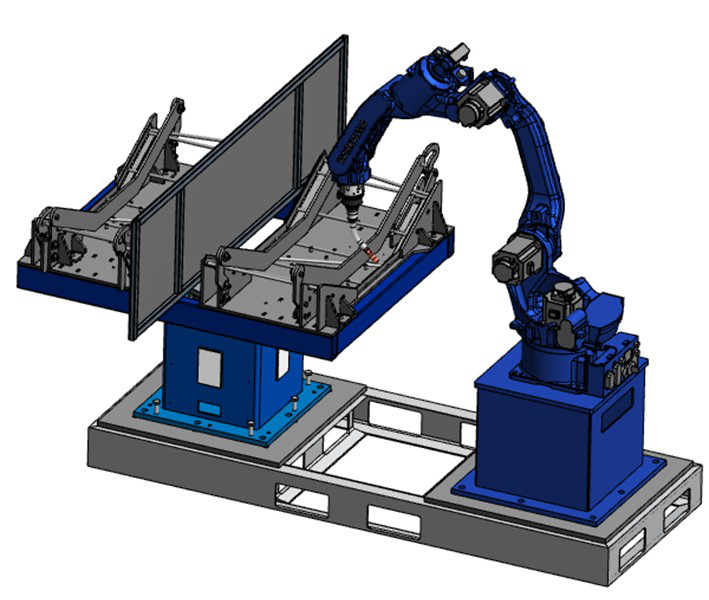

Another robotization project has been successfully completed; this is already the second robotic complex that we have supplied to this plant, located in the city of Belaya Tserkov, Kiev region. The delivered complex is a TRIADA-ROBO standardized welding solution.

The company "Grain House" is a Ukrainian plant for the production of elevators and elevator equipment, the main partner of which is the American company "Sukup", which occupies a leading position in the international market. The company's activities are aimed at providing a wide range of services for the manufacture and construction of elevator facilities, as well as their comprehensive maintenance. Probably, many of you, when traveling across Ukraine, noticed huge metal cylindrical structures standing along the tracks, in the night moonlight they resemble spaceships. These are bunkers for cooling and storage of grain, overpasses, which are produced by the "Grain House".

.png)

The first complex has already worked more than 18000 hours since 2018 and operates in 3 shifts. 3 scheduled maintenance was performed every 6000 hours.

The second complex is equipped with the latest model of equipment, which requires maintenance once every 12000 hours, so the Customer will save money on this.

We have developed a technology for transferring technological programs from the complex with the previous equipment to the complex with the supplied equipment, so the launch of the new complex after installation for welding took only 1 day. Together with the installation, the equipment was launched in 3 days for in-line welding.

Together with the delivery of the complex, the TRIADA TES service was implemented (Technological Engineering Support - technological engineering support from the Triada.)