We have developed unique robot modules for the general public and formed them into a line of ready-made solutions that can be selected and applied in production. These solutions have the value of a combination of economy, environmental friendliness, universality at the deep level of all our knowledge, skills, will to technological balance.

The robotic link Triada-Robo is a unique and universal product.

The robotic link for welding of TRIADA-ROBO W10-700

Characteristics of the robotic unit:

For welding of those products in which placement of seams does not require edging of this product on a positioner in the course of welding. The welding complex is compact, insulated on all sides and has an inlet for connecting the exhaust ventilation.

The maximum size of the working area of the complex:

700 x 400 x 300 mm

Complete set:

- Yaskawa industrial robot - 1 amount

- digital welding system with gas cooling on 320A - 1 piece

- BASIC operator's panel - 1 piece

- equipment integration

- installation of equipment

- training of the Customer's personnel in programming and operation of the robotic complex.

The robotic link for welding of TRIADA-ROBO W10-1440 / 2010 / 3120

Characteristics of the robotic unit:

For welding of those products in which placement of seams does not require edging of this product on a positioner in the course of welding.

The maximum size of the working area of the complex:

1440mm / 2010mm / 3120mm

Complete set:

- Yaskawa industrial robot - 1 piece

- Digital welding system with gas cooling on 320A - 1 piece

- Burner cleaning station - 1 pc.

- The BASIC operator's panel - 1 piece

- Equipment integration

- Installation of equipment

- Training of the Customer's personnel in programming and operation of the robotic complex.

The robotic link for welding of TRIADA-ROBO W11-1440.70P / 200

Characteristics of the robotic unit:

For welding of those products in which placement of seams does not require edging of this product on a positioner in the course of welding. The complex is designed for mass production.

Maximum length of a welding product: to 1000 mm

Maximum diameter of a welding product: to 600 mm

Maxim. weight of a product taking into account equipment: 70 kg / 200 kg

Complete set:

- Yaskawa industrial robot - 1 piece

- Positioner uniaxial pneumatic for two stations with a capacity of 70 kg / 200 kg - 1 pc.

- Digital welding system with gas cooling - 1pc.

- Burner cleaning station - 1 pc.

- The BASIC operator's panel - 1 piece

- Equipment integration

- Installation of equipment

- Training of the Customer's personnel in programming and operation of the robotic complex

The robotic link for welding of TRIADA-ROBO W11-2010.500

Characteristics of the robotic unit:

For welding of products with a possibility of rotation on one axis. The complex is designed for a small batch of parts or for parts in which the welding time in relation to the time of assembly, loading and unloading is more than 80%.

The maximum length of a welding product to 2900 mm

The maximum diameter of a welding product to 1400 mm

The maximum weight of a welding product taking into account equipment is 500 kg

Complete set:

- Yaskawa industrial robot - 1 piece

- The positioner is uniaxial with a loading capacity of 500 kg - 1 piece

- Welding joint search system - 1 pc.

- Digital welding system with gas cooling - 1pc.

- Burner cleaning station - 1 pc.

- The BASIC operator's panel - 1 piece

- Equipment integration

- Installation of equipment

- Training of the Customer's personnel in programming and operation of the robotic complex.

The robotic link for welding of TRIADA-ROBO W12-2010.200

Characteristics of the robotic unit:

For welding of products with a possibility of rotation on one axis. The complex is designed for a large batch of parts, because the two positioners provide greater production efficiency.

The maximum length of a welding product to 2900 mm

The maximum diameter of a welding product to 1400 mm

The maximum weight of a welding product taking into account equipment is 200 kg

Complete set:

- Yaskawa industrial robot - 1 piece.

- Positioners uniaxial pneumatic two-position with a loading capacity of 200 kg - 2 pieces.

- Welding joint search system - 1 pc.

- Digital welding system with gas cooling - 1pc.

- Burner cleaning station - 1 pc.

- The BASIC operator's panel - 1 piece.

- Equipment integration

- Installation of equipment

- Training of the Customer's personnel in programming and operation of the robotic complex.

The robotic link for welding of TRIADA-ROBO W13V-2010.2050

Characteristics of the robotic unit:

For welding of products with a possibility of rotation on one axis. The complex is designed for a large batch of parts.

- The maximum length of a welding product to 1900 mm

- The maximum diameter of a welding product to 1500 mm

- The maximum weight of a welding product taking into account equipment is 500 kg

Complete set:

- Yaskawa industrial robot - 1 piece.

- Positioner three-axis with a loading capacity of 500 kg - 1 piece

- Digital welding system with gas cooling - 1pc.

- Burner cleaning station - 1 pc.

- The BASIC operator's panel - 1 piece.

- Equipment integration

- Installation of equipment

- Training of the Customer's personnel in programming and operation of the robotic complex.

The robotic link for welding of TRIADA-ROBO W13Н-2010.3000

Characteristics of the robotic unit:

For welding of products with a possibility of rotation on one axis. The complex is designed for a large batch of parts.

- The maximum length of a welding product to 2900 mm

- The maximum diameter of a welding product to 1100 mm

- The maximum weight of a welding product taking into account equipment is 500 kg.

Complete set:

- Yaskawa industrial robot - 1 piece.

- Positioner three-axis with a loading capacity of 500 kg - 1 piece

- Digital welding system with gas cooling - 1pc.

- Burner cleaning station - 1 pc.

- The BASIC operator's panel - 1 piece.

- Equipment integration

- Installation of equipment

- Training of the Customer's personnel in programming and operation of the robotic complex.

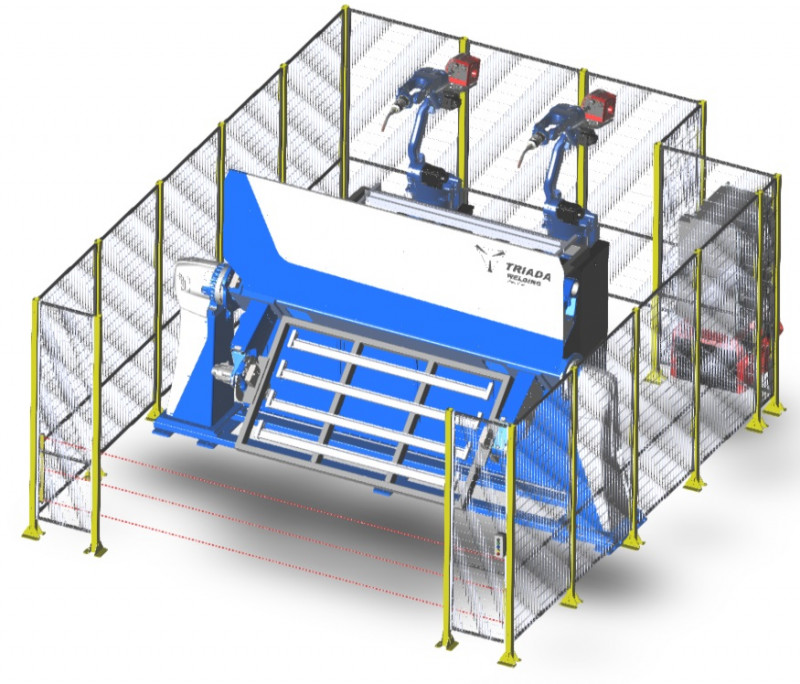

The robotic link for welding of TRIADA-ROBO W23V-1440.2050

Characteristics of the robotic unit:

For welding of products with a possibility of rotation on one axis. The complex is designed for a large batch of parts, because the two works provide greater production efficiency.

- The maximum length of a welding product to 1900 mm

- The maximum diameter of a welding product to 1500 mm

- The maximum weight of a welding product taking into account equipment is 500 kg

Complete set:

- Yaskawa industrial robot - 2 pcs.

- Positioner with a load capacity of 500 kg - 1 piece.

- Digital welding system with gas cooling - 2 pcs.

- Burner cleaning station - 1 pc.

- The BASIC operator's panel - 1 piece.

- Equipment integration

- Installation of equipment

- Training of the Customer's personnel in programming and operation of the robotic complex.

The robotic link for welding of TRIADA-ROBO W23H-1440.3000

Characteristics of the robotic unit:

For welding of products with a possibility of rotation on one axis. The complex is designed for a large batch of parts, because the two works provide greater production efficiency.

- The maximum length of a welding product to 2900 mm

- The maximum diameter of a welding product to 1100 mm

- The maximum weight of a welding product taking into account equipment is 500 kg

Complete set:

- Yaskawa industrial robot - 2 pcs.

- Positioner with a load capacity of 500 kg - 1 piece.

- Digital welding system with gas cooling - 2 pcs.

- Burner cleaning station - 1 pc.

- The BASIC operator's panel - 1 piece.

- Equipment integration

- Installation of equipment

- Training of the Customer's personnel in programming and operation of the robotic complex.

The robotic link for service of the automatic molding machine TRIADA-ROBO (1А)

Characteristics of the robotic unit:

The complex is designed for the manufacture of plastic products by injection molding. Reliable security system and fencing of the robotic complex. Drives for finished products.

Complete set:

- Yaskawa industrial robot

- BASIC operator panel

- Metal pedestal for mounting the robot to the floor

- Two-stage compressed air purification system with pressure sensor

- Capture for industrial robot

- Drive for industrial robot

- Security system and fencing of the robotic complex

- Service of integration of the robotic complex with the automatic molding machine

- Installation of equipment

- Robotic complex programming

- Staff training in programming and operation.

Robotic link for shifting bricks TRIADA-ROBO В20

Characteristics of the robotic unit:

The complex is designed for laying bricks. Two robots provide high production efficiency.

Loading capacity taking into account the weight of capture of 190 kg

Complete set:

- Yaskawa industrial robot - 2 pcs.

- Pneumatic gripper for Yaskawa robot - 2pcs.

- The BASIC operator's panel - 2 pieces.

- Metal pedestal for the location of the work - 2pcs.

- Equipment integration

- Installation of equipment

- Training of the Customer's personnel in programming and operation of the robotic complex.

Robotic link for milling TRIADA-ROBO F11

Characteristics of the robotic unit:

Complex for machining parts, namely milling, which includes a positioner with a vertical axis of rotation. Spindle for milling with a power of 10 kW, with a load of PV - 100%.

Complete set:

- Yaskawa industrial robot - 1 pcs.

- Positioner with Yaskawa servomotor with vertical axis of rotation - 1pc.

- BASIC operator panel - 1 piece.

- Metal pedestal for the location of the work - 1pc.

- Spindle for milling - 1 piece.

- Software for processing products by 3D model

- Equipment integration

- Installation of equipment

- Training of the Customer's personnel in programming and operation of the robotic complex.

TRIADA-ROBO education robotized module

We have developed a unique robot module TRIADA-ROBO S10-706 for training, which can be widely used not only to train students of educational institutions, but also to train a wide range of specialists of industrial enterprises in various fields of production.

This solution has the value of a combination of economy, environmental friendliness, universality at the deep level of all our knowledge, skills, will to technological balance.

Characteristics of the robotic unit:

- the robotic complex is equipped with an industrial robot with 6 axes;

- the robot is equipped with a full-fledged industrial controller and programming console;

- as an option, it is possible to purchase a special software license for educational institutions for offline programming of the robotic complex from one to forty computers;

- the executive element of the work is a pneumatic gripper, which has the ability to use replaceable pads for different shapes of parts;

- the robotic cell has a completely closed cabin body, the door is equipped with a security sensor;

- there is an integrated operator panel with three freely programmable buttons, reset buttons and an emergency stop button;

- the robotic cell and the controller are mounted on wheels, so they are easy to move;

- the guaranteed service life of the robotic cell is 15 years.

Having learned to program a robot in a training cell, the operator acquires complete knowledge for programming an industrial robot in manufacturing plants.

|

|